Modern Underground Electrical Line Insulation: From Jute to Advanced Polymers

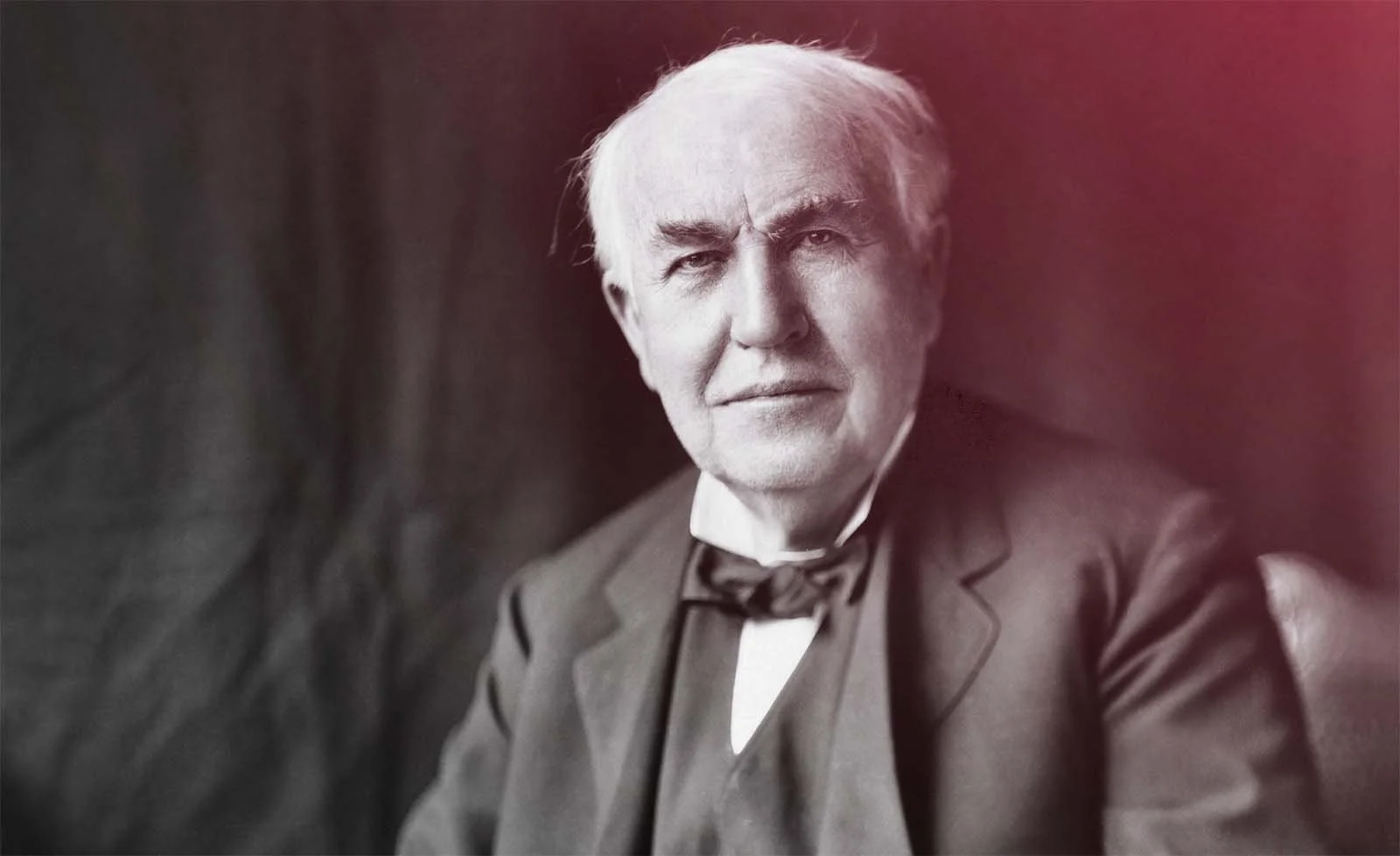

The journey of underground electrical cables has evolved dramatically since Thomas Edison first electrified New York City’s streets in the 1880s. Edison, a pioneer in electrical power distribution, initially laid down underground DC "street pipes" as part of his early power networks. These cables, running under the bustling streets, were insulated with jute, a plant fiber treated with tar to shield the wires from moisture. However, this early method faced issues like deterioration from the elements and limited lifespan. Recognizing these shortcomings, Edison switched to rubber insulation by 1882, which marked a significant leap in durability and safety.

The Evolution of Insulation Materials

From Edison’s rubber insulation to today’s advanced materials, the technology behind underground electrical line insulation has seen remarkable progress. Modern underground cables are now insulated with materials like Cross-Linked Polyethylene (XLPE) and ethylene propylene rubber (EPR).

XLPE is highly resistant to thermal stress, chemical exposure, and moisture, making it ideal for high-voltage applications.

EPR offers flexibility and excellent resistance to temperature changes, which is crucial for maintaining performance in varied environmental conditions.

These materials not only provide robust insulation but also extend the lifespan of cables, reducing maintenance needs and improving reliability in power distribution.

Why Bury Electrical Lines?

Burying electrical lines offers several key safety and reliability advantages over overhead power lines:

Reduced Risk of Accidents: Underground cables are far less likely to come into contact with people, animals, or vehicles, reducing the risk of electrocution and fire hazards.

Weather Resistance: Underground lines are protected from severe weather conditions like high winds, heavy rain, ice storms, and lightning, which are common causes of power outages for overhead lines.

Improved Aesthetics and Safety: Removing overhead lines eliminates visual clutter and reduces the risk of power lines being damaged by falling trees or branches.

The shift from simple jute insulation to today’s advanced polymers is a testament to the ongoing innovation in electrical engineering. As cities expand and demand for reliable power grows, underground cables continue to play a crucial role in delivering safe, consistent electricity, following in the visionary footsteps of Edison’s early work.

A Final Note

Edison’s journey from jute to rubber insulation was just the beginning. Modern materials like XLPE and EPR have revolutionized the way we insulate and protect underground cables, ensuring reliable power delivery in an increasingly electrified world. By burying these lines, we embrace safer and more resilient power distribution, keeping the lights on in our homes, businesses, and cities.